Description

BASIC MACHINE

Basic machine Tectra 6120 CLASSIC, cutting length 4400 mm

Air flotation machine table, crosscut fence on the left side

TECHNICAL SPECIFICATIONS

Modular Construction of the basic machine ensures perfect adjustment to your space and cutting requirements.

Control panel, crosscut fence and tool change on the left side ?- short distances

Saw cycle away from the fence – very short cycle times, also when doing manual cutting operations

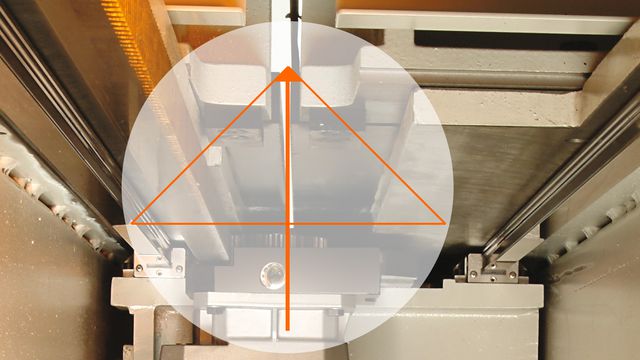

Machine base – sophisticated welded construction which is optimized in every detail. Allows the use of high precision linear guidings (CNC technology. Can be crane lifted / transported in the center, on the left or the right side.

Air cushioned machine table – the air cushion between the material to be cut and the machine table prevents scratching of sensitive materials and relieves the turning of the sheet.

(only for option: air cushioned version)

Pusher speed forward 25 m/min. according to CE

Pusher speed backward 100 m/min – short times for positioning the sheets

Pressure beam – welded steel construction, very high torsion stability.

Variable pressure adjustment – to prevent the damage of sensitive materials or for high pressure when cutting sheet staples

Rest cutting device in the pressure beam – clamps move into the groove of the pressure beam – segmentation without a rest is possible. Perfect utilization of the entire sheet.

PUSHER

Programmable automatic pusher 4250 mm, for cutting length 4400

Heavy duty steel construction – extremely stiff – guided by linear bearings and guide ways.

Positioning via direkt drive motors and rack and pinion drive on both sides of the pusher.

Touch free mangnetic dimensioning system with continous check-up.

Opening dimension for clamps max. 82 mm for length- and cross-cuts.

TABLES

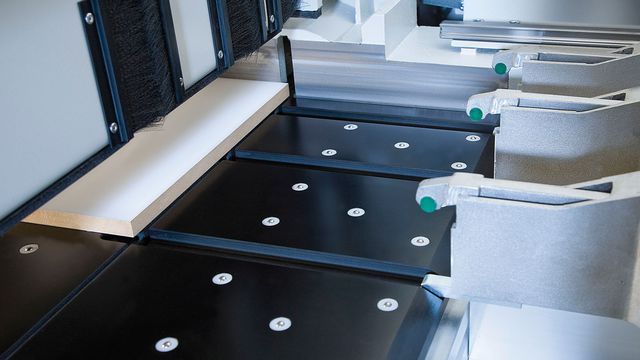

Angle – air floatation support table 1800 with stop fence

Table size 1800 mm x 600 mm, mounted to the basic machine

To avoid scratches on the surface of the material and for an easy handling while turning and moving the material

2 additional air floatation support tables 1800

Table size 1800 mm x 600 mm, mounted to the basic machine

To avoid scratches on the surface of the material and for an easy handling while turning and moving the material

SAW CARRIAGE

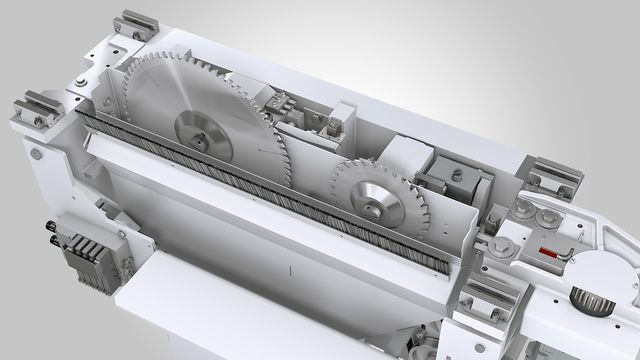

Saw carriage, cast iron construction

Precisely guided saw carriage with rack gear and hardened linear guides

Main saw motor 7,5 kW

Sawblade projection max. 82 mm

Main sawblade: ? 350 x 4.4 x 30 mm, Z 72 FZ/TZ, 2/10/60

Saw carriage:

Feed speed of saw carriage: 0 – 70 m/min

electronically controlled, continuously adjustable

Reverse of carriage: 70 m/min

Automatic, variable adjustment of cutting height

Motor driven groove height adjustment – Groove depth adjustable 0 – 30 mm, programmable via control unit and via optimizing software (only with option Opti Cut).

Optimizing bi-directional grooving (FCM) Fast-Cut-Modus ensures shortest cycle times while grooving as also the return of the saw carriage is used for the actual grooving process

Automatic, variable cutting height adjustment – the ideal saw blade projection is calculated by using a sensor on the pressure beam, measuring the actual height of the panel(s), and by entering the adjustable sawblade protrusion.

Quick change and locking system – for the main and the scoring sawblade. Ensures high precise clamping of the sawblades as well as very short times for the change of the saw blade.

Automatic cutting length detection – Recognizes the length of the workpeice by a touchless sensor – no unnecessary movements of the saw carriage, especially when doing manual cuts.

Blow off device – for cleaning the cutting length detection sensor during the cutting process when cutting dust intensive materials.

Scoring unit motor 2,2 kW

No loss of power when cutting very hard coatings.

Electric adjustable scoring saw – ensures a simple and very accurate adjustment of the scoring saw via the monitor in no time with minimum effort.

HM-Scoring saw blade ? 180 x 4,4/5,4 x 30 mm conic, 2/10/60

ELECTRICAL

Saw carriage standard 7.5 KW, 400V 50/60 Hz – 4400 mm

DUST EXTRACTION

Dust extraction – the dust-flow optimized saw carriage is directly connected to a chip channel designed for all kinds of dust and chips.

This guarantees a consistent extraction result for many years to come.

SIDE ALIGNMENT

Side alignment cutting leghth 4400, pneumatic controlled,

Variable up to 1200 mm, guarantees precise perpendicular cuts

Pressure is pneumatically variable adjustable

WORKPIECE CLAMPS

Rear clamping devices, floating clamping action

compensates variations within the panel pack

> 5 clamps at 3,100 mm cutting length

> 6 clamps at 4,400 mm cutting length

OPERATION AND CONTROL

Control unit at the side of the fence and the sawblade change ensures shortest ways

Control unit CUTCONTROL 2 with 21,5″ TFT display

EasyLabel – Label printer for HOLZ-HER machines

Label printer for direct connection to machine PC

For text and barcode prints (universal product code and 2D Data-Matrix) Integrated software for labels with test and barcode print. Label template editor to link with label variables.

OPTIMIZING SOFTWARE

EASY-PLAN – dongle version:

Especially designed software for the quick and simple optimization of cutting list directly at the machine. Well arranged and clear layout, variable input areas.

GUARANTEE

The warranty period for the machine is 12 months for one-shift operation.

Reviews

There are no reviews yet.