Description

BASIC MACHINE

BASIC MACHINE STREAMER 1057XL 200 – 400 V / 50 Hz, with manual pressure bridge adjustment

Rigid workpiece support XL type, distance 380 mm

TECHNICAL SPECIFICATIONS

Edgebander for the edging and post-machining of materials in panel form

Edging thickness of coiled edging: 0,4 – 3 mm

(depending on material)

Edging thickness of cut-length edging: 0,4 – 6 mm

(depending on material)

Edging cross section: max. 6 x 42 mm

Edging height: max. 65 mm

Panel thickness: 8 – 60 mm

(limitation possible in case of individual units)

Workpiece width: min. 65 mm

Workpiece length: min. 160 mm (without corner copying unit 1832) Workpiece length: min. 180 mm Feed speed: 10 m/min.

OPERATION

Turnable and tiltable control panel, ergonomically located on the inlet side with selector switches for adjusting the units with temperature control for the heating circuits in the adhesive application system

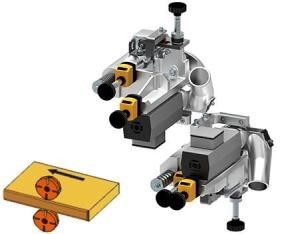

PRE-MILLING UNIT

Pre-milling unit FG201 with 2 cutter units for jointing the panel edge

1x counter clockwise run, 1x clockwise run manually adjustable run-in linear stop, with patented ProLock screw-in clamping system for rapid tool change with adjustable cutters

Diamond cutter Ø 70 x 48 x 30 mm, 2+2 teeth, left hand Air Stream System (HOLZ-HER / LEUCO patent) For pre-milling unit 1801 / 1802

Diamond cutter Ø 70 x 48 x 30 mm, 2+2 teeth, right hand Air Stream System (HOLZ-HER / LEUCO patent) For pre-milling unit 1801 / 1802

EDGE FEEDER

Edge feeder 1903

Automatic transport of coils and single strips max. load capacity: 40 mm

max. edge thickness 3 mm (material dependent) forward cut up to max. 65 mm (material dependent) max cross section 135 mm² (material dependent) support table for coils Ø 820 mm

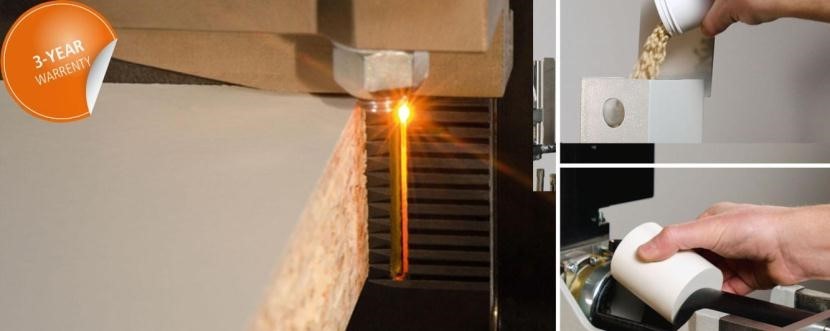

GLUE APPLICATION

Glue application system Glu Jet GJ301 (2,3 kW, 50 Hz)

Automatic adjustment of gluing height (tracing nozzle)

Glu Jet hybrid technology

Processing of EVA and PUR adhesives

Adhesive in cartridge or granules form

Processing of neutral and coloured adhesives

For processing hot-melt adhesive in cartridge or granules form Glue applied by means of nozzle technology, heat-up time: 3 minutes

Manual reloading of glue from the control panel

Incl. manual glue rinse function through separate rinse channel

Magazine capacity: 1 cartridge (approx. 330 g)

Incl. air pressure adjustment for the glue pressing cylinder

Automatic glue temperature reduction according to time

Hopper for 1,5 kg glue granulate

Hopper for 1,4 kg glue cartridges (4 cartridges)

PRESSURE UNIT

Pressure unit 1912-3 pneumatic

first roller driven with plunge-in control, 2 conical support pressure rollers

END TRIMMING UNIT

End trimming unit 1918 (60 mm) pneumatic

Chamfer-type end trimming 0/10 degrees, pneumatic adjustment incl. 2 alternating teeth carbide circular saw blades, Ø 110 mm, 20 teeth

MULTIFUNCTIONAL TRIMMING UNIT

Trimming unit FR201 (2 x 0.6 kW, 300 Hz, 18,000 min-1)

Multipurpose unit for flush trimming, radius and chamfering

Diamond cutter Ø 57 x 17 mm Z = 2, R = 2,0 mm, left hand diamond coated, permanently equipped tool with CM technology (LEUCO), with integrated chip removal patented ProLock screw-in clamping system for rapid tool change for multifunctional trimming unit FR201

Diamond cutter Ø 57 x 17 mm Z = 2, R = 2,0 mm, right hand diamond coated, permanently equipped tool with CM technology (LEUCO), with integrated chip removal patented ProLock screw-in clamping system for rapid tool change for multifunctional trimming unit FR201

FORM TRIMMING

Corner rounding unit 1832 (1 x 0,22 kW, 300 Hz, 9000 min -1) corner copying function up to 3 mm edging thickness

workpiece thickness: 12 – 60 mm, incl. diamond tool R = 2 mm with CM technology, incl. automatic plunge-out control for edge thickness over 8 mm (max. feed speed 10 m/min.)

Diamond coated tooling Ø 53 mm x 10 mm x 16 mm, Z = 3, R = 2 mm with CM technology (LEUCO system), with integrated chip removal, for corner rounding unit 1832

SCRAPER UNIT

Scraper unit 1929 with 2 scraper carriers, incl. change-over plates R = 2,0 mm with 2 digital counters for horizontal sensing rollers and chip removers

Workpiece thickness: min. 12 mm

Chip collector for scraper unit 1929

Surface scraper unit 1964 (instead of Buffing unit 1940)

For scraping off the glue residue to achieve a clean glued join Controlled at top and bottom, incl. 2 blowing nozzles, incl. 2 HM change-over blades

Buffing unit 1940 (2 x 0.09 kW, 50/60 Hz, 1,400 min-1)

For cleaning and edge polishing, with 2 textile discs, pivotable 0 – 5°

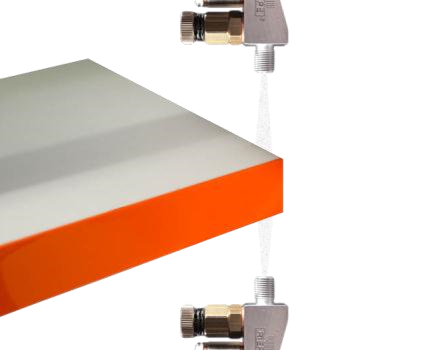

SPRAYER UNIT

Sprayer 1856 for the in- and outfeed area

For the infeed area: Electronically controlled release agent sprayer with release agent

For the outfeed area: Electronicaly controlled cleaning agent sprayer with cleaning agent

Reviews

There are no reviews yet.